Complete Breakdown of Hardwood Flooring Types: Solid, Engineered, Exotic & More

Table of Contents

Hardwood flooring never goes out of style. It delivers natural warmth, timeless character and resale value that few other surfaces can match. Yet choosing the right type of hardwood can be daunting because the category now includes everything from traditional solid planks to multi‑layered engineered boards and reclaimed barnwood.

Understanding the differences between these products is the key to a floor that performs well in your home’s climate, fits your budget and reflects your taste.

This guide compares the major categories—solid hardwood, engineered hardwood, exotic species, hand‑scraped and prefinished boards, reclaimed lumber and even sustainable alternatives like bamboo and cork—and explains where each excels. It also offers selection tips on species hardness, installation, moisture resistance and long‑term cost so you can make an informed decision.

Solid Hardwood: Traditional Craftsmanship and Timeless Appeal

Construction and Features

Solid hardwood planks are milled from a single piece of wood, usually about ¾ inch thick. Because each plank is one solid piece, the floor can be sanded and refinished multiple times over its lifetime, which makes it exceptionally long‑lasting.

Domestic species such as oak, maple, hickory and walnut dominate the solid‑wood market and can last decades with proper care. Solid boards offer unmatched authenticity—the grain, knots and color variations are all natural—and their mass contributes to excellent sound absorption and a sturdy feel underfoot.

Pros of Solid Hardwood

- The main advantage of solid hardwood is longevity.

- Planks can be sanded and refinished repeatedly to refresh worn finishes or change the stain color.

- Solid wood is also considered a high-end material that can boost resale value; many buyers prefer it for its authenticity.

Cons of Solid Hardwood

- Solid wood is vulnerable to moisture and temperature fluctuations.

- Because it expands and contracts as humidity changes, manufacturers recommend installing it only above grade (not in basements) and in homes with controlled humidity.

- Nail-down installation is required over plywood subfloors, which adds labor cost.

- Solid wood often carries higher upfront costs for both materials and installation.

Species Options and Hardness

Oak remains the most popular species, composing roughly two‑thirds of installed hardwood floors. Red oak has a Janka hardness of 1,290 and white oak 1,360, offering a good balance of durability and workability. Maple (Janka 1,450) provides a lighter appearance and fine grain, while hickory (Janka 1,820) is one of the hardest domestic woods.

Walnut is prized for rich brown hues but is softer (Janka ~1,010). Domestic cherry have a Janka rating of around 950, giving it a softer feel and making it more prone to dents. Because the Janka scale measures resistance to denting and wear, floors in high‑traffic homes should have a rating above 950. Costs typically range from $3–$10 per square foot for maple and $2–$8 for oak.

Engineered Hardwood: Modern Stability and Versatility

Construction and Benefits

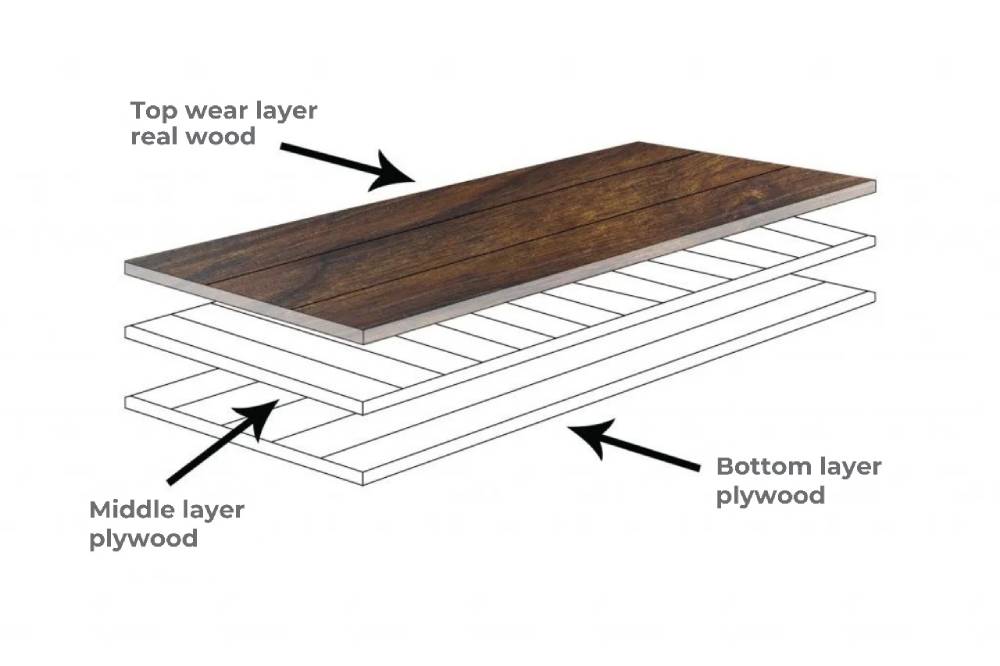

Engineered hardwood uses a thin veneer of real wood bonded to layers of plywood or high‑density fiberboard (HDF). This multi‑ply construction stabilizes the plank, reducing expansion and contraction from humidity changes. The result is a floor that can be installed in places where solid hardwood struggles, such as basements, over concrete slabs and radiant‑heat systems.

Engineered boards still offer the look and feel of real wood because the top layer is genuine hardwood, but they are less likely to cup or warp under moisture. Many engineered products are prefinished at the factory, providing durable coatings and a quick installation.

Durability and Layers

Engineered flooring quality varies by the number of plies and the thickness of the wear layer. Good‑quality products may have three plies and a 1–3 mm wear layer, while better grades use five plies and a 3–7 mm wear layer.

Best‑in‑class boards employ seven or more plies with a 3–9 mm wear layer and robust warranties. A thicker wear layer allows limited sanding—typically one or two refinishes. Engineered floors cannot be sanded as many times as solid hardwood, but quality products can still last decades with proper care.

Installation and Cost

One of the biggest advantages of engineered wood is versatility. Planks can be nailed, glued or floated depending on subfloor and room conditions. Floating installations allow DIYers to click planks together without adhesives, reducing labor costs. Because the core layers use less expensive plywood, engineered boards are often cheaper than solid wood and easier to install.

They also acclimate faster and don’t need the lengthy site finishing that unfinished solid planks require. Many engineered floors come with durable factory‑applied finishes that carry 25‑ to 50‑year warranties.

Comparing Engineered and Solid Wood

The primary difference between engineered and solid hardwood is construction. Solid wood is a single piece of timber, while engineered uses a veneer over a stable core. Both can last decades, but solid can be sanded more often.

Engineered boards are more dimensionally stable and resistant to humidity and temperature swings, making them suitable for basements and radiant‑heat systems. Price typically favors engineered wood, though high‑quality products can rival solid wood costs. When installed and maintained correctly, both types add resale value; buyers often gravitate toward solid wood for its reputation, but engineered floors appeal to homeowners seeking modern performance.

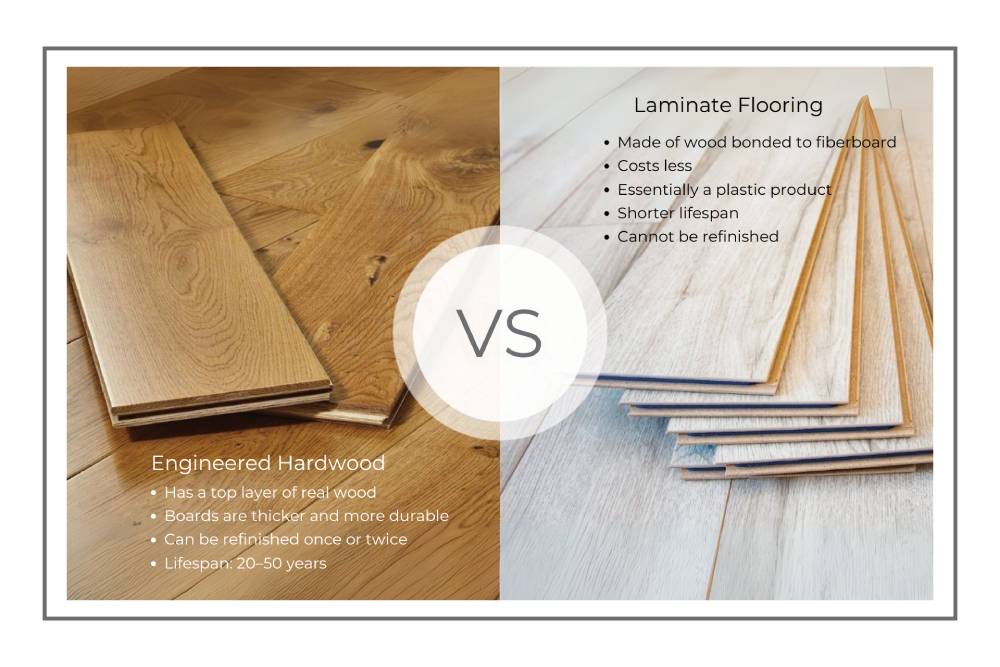

Engineered vs. Laminate

It’s important not to confuse engineered hardwood with laminate flooring. Engineered wood has a top layer of real wood, while laminate is a high‑resolution photograph of wood bonded to a fiberboard. Engineered boards are thicker and more durable, can be refinished once or twice and have a 20–50 year lifespan. Laminate costs less but is essentially a plastic product with a shorter lifespan and cannot be refinished.

Exotic Hardwood: Distinctive Species and Vibrant Colors

What Makes a Wood Exotic?

Exotic hardwoods refer to species imported from tropical regions. They often feature dramatic grain patterns, rich colors and exceptional hardness. The unique look can dramatically elevate a room’s design and set it apart from standard oak or maple floors. However, exotic wood tends to be pricier due to import costs and may raise sustainability concerns.

Popular Species and Hardness

Some of the most sought‑after exotics include:

- Brazilian cherry (Jatoba): Known for deep reddish‑brown tones and a Janka rating around 2,350 , nearly twice as hard as red oak. Its intense color darkens over time, creating a luxurious, mature look.

- Tigerwood: Displays striking variegated stripes of orange and brown. It has a high Janka rating and excellent durability; pricing is often similar to other exotics.

- Acacia: Offers a range of colors from golden tan to dark brown with bold grain variations; it is durable and dimensionally stable.

- Brazilian walnut (Ipe): Extremely dense (Janka 3,680) and naturally rot‑resistant, often used for outdoor decking. Indoors it provides a dark, sophisticated look.

Because exotics are so hard, they resist dents and scratches well but can be difficult to mill or sand. Prices typically start around $8–$15 per square foot for Tigerwood and Acacia and can exceed $20 per square foot for Jatoba or Ipe.

Pros of Exotic Woods

- Score high on durability and visual impact.

- Density and hardness reduce wear.

- Natural oils in many species contribute to moisture resistance.

Cons of Exotic Woods

- Imported wood often costs more to ship.

- May involve questionable logging practices.

- Behave like solid hardwood in installation; they should be acclimated and nailed down.

- Because of their density, they can dull blades and may need pre-drilling for fasteners.

Sustainability of Exotic Woods

- Look for certifications like the Forest Stewardship Council (FSC) to ensure ethical harvesting.

Hand‑Scraped, Distressed and Prefinished Boards

Hand‑Scraped and Distressed Styles

Hand‑scraped hardwoods are intentionally textured to create a rustic, time‑worn appearance. Boards are scraped or wire‑brushed to highlight grain and mask minor scratches. This makes them ideal for busy households with pets or children because the irregular texture conceals wear. Hand‑scraped floors come in both solid and engineered formats and are often factory finished with durable coatings.

Prefinished vs. Unfinished Hardwood

Prefinished boards arrive from the factory with multiple coats of finish already applied. This provides a uniform, durable coating and speeds installation; there’s no need to sand, stain and seal on site.

Factory finishing allows manufacturers to apply hard, UV‑cured urethane finishes that are difficult to replicate in the field.

Unfinished floors, on the other hand, are installed raw and then sanded, stained and sealed in place. This takes longer and is messier, but it allows for custom stain colors and perfectly flush joints. Modernize notes that finished floors carry manufacturer warranties and reduce installation time, while unfinished floors provide a seamless look and customizable color.

Reclaimed and Eco‑Friendly Alternatives

Reclaimed Hardwood

Reclaimed wood comes from deconstructed barns, factories and homes. Planks often bear saw marks, nail holes and patina, giving them unmatched character. Because the wood is recycled, it’s also environmentally friendly and doesn’t require new trees.

Reclaimed boards can be solid or engineered; they may cost more due to sourcing and processing, but they appeal to homeowners seeking unique, eco‑conscious flooring.

Bamboo and Cork

While not technically hardwoods, bamboo and cork are popular alternatives in the “wood‑look” category. Bamboo is a grass that regenerates in as little as three years, making it an eco‑friendly option. Strand‑woven bamboo has a Janka rating of around 1,380 and costs $5–$15 per square foot.

Cork is harvested from the bark of cork oak without cutting down the tree; it offers cushioning underfoot and natural resistance to mold and pests. However, both materials require careful manufacturing to avoid high emissions of formaldehyde or other toxins, choose products with low‑VOC certifications.

Cork Plank Flooring

Cork’s cellular structure makes it compressible and comfortable. It provides insulation and sound absorption while remaining hypoallergenic. Cork planks are usually prefinished with polyurethane; the surface can be dented by heavy furniture, but springiness allows minor indentations to rebound. Use cork in bedrooms, playrooms or offices where comfort matters. Avoid high‑moisture areas unless the product is specifically engineered with a protective core.

How to Choose the Right Hardwood Flooring

Selecting the best hardwood type depends on four primary factors: environment, use patterns, aesthetic goals and budget. The following sections break these factors down so you can match each to the appropriate flooring type.

Assess Your Environment and Subfloor

Moisture and Climate

Homes with fluctuating humidity or below‑grade rooms should lean toward engineered hardwood because of its dimensional stability. Basements, condos with concrete slabs and radiant‑heat systems benefit from engineered planks that can be glued or floated. In dry, climate‑controlled homes, solid wood is feasible on main levels and over plywood subfloors.

Evaluate Traffic and Wear

Foot Traffic and Pets

High‑traffic households with children, pets or heavy furniture might favor hard domestic species (hickory, maple) or even exotic woods for scratch resistance. Hand‑scraped and distressed finishes conceal dents. Engineered floors with thicker wear layers (3–7 mm) can be sanded once or twice, extending their lifespan. For formal living rooms or dining areas where traffic is light, softer species like walnut or cherry are acceptable.

Consider Style and Design

Aesthetic Preferences

Wide planks, matte finishes and neutral tones are trending for 2025. Both solid and engineered products now offer similar colors and textures thanks to manufacturing advances.

Exotic woods deliver bold statements with deep hues and unique grains. Hand‑scraped surfaces bring rustic charm, while sleek, smooth boards suit contemporary interiors. Choose stains or species that complement your cabinetry, wall color and furniture.

Balance Initial Cost and Long‑Term Value

Budget Considerations

Solid hardwood generally costs more to purchase and install but can be refinished multiple times, making it a wise investment for “forever” homes. Engineered wood offers a lower upfront price, quicker installation and comparable aesthetic value. If you expect to move within 10–15 years, engineering may be the more pragmatic choice.

Exotic species command premium prices but may add luxury appeal in high‑end markets. Reclaimed and eco‑friendly alternatives typically cost more than entry‑level wood but offer sustainability and uniqueness.

Final Thoughts

Hardwood flooring provides a unique combination of warmth, beauty and durability. Solid hardwood remains the gold standard for authenticity and longevity, but its susceptibility to moisture makes it best suited for stable environments. Engineered hardwood uses modern technology to combine real wood aesthetics with superior stability, making it ideal for basements, condos and radiant‑heat systems.

Exotic species offer exceptional hardness and striking visuals, while hand‑scraped and prefinished boards provide convenience and rustic charm. Reclaimed wood, bamboo and cork appeal to eco‑conscious homeowners looking for sustainable alternatives.

When choosing your floor, consider climate, subfloor, traffic patterns, budget and design goals. Use the Janka scale to ensure adequate hardness, and don’t overlook installation and maintenance requirements. With the right information, you can select a hardwood floor that enhances your home’s beauty, withstands daily life and delivers lasting value.